The Difference Between MG and MF Paper

Many of the questions that we receive here at Flexlink deal with the differences between “MG” or “machine glazed” paper versus “MF” or “machine finished” kraft paper. People often ask us, “What is the difference between the two?” or, “Why does my paper have a shiny surface?” or even, “It looks like this paper has a waxy or coated surface; what is that all about?” Therefore, we thought we would take a few minutes to describe the difference between MF and MG Paper so you can have a better understanding.

The Drying Difference Between MG and MF

The papermaking process starts on the wet end of the paper machine. Pulp is mixed with water in a ratio of 99.5% water and .5% pulp, but most of the water is drained from the pulp mixture by the time the paper hits the drying section. At the start of the drying section, the paper is still 40% water.

The drying section uses steam heated drying cans to dry the paper to between 4% and 6% moisture, which is the moisture range for most papers that are made today. The only difference between MF and MG paper is in the way the two different papers are dried while they are in the drying section of the paper machine.

MF Paper: Dried by a Series of Dryers

MF paper is dried by sending the paper through a series of drying cans that dry the paper from both the top and the bottom of the sheet, thereby imparting nearly the same level of smoothness on both sides of the paper. Examples of commodity papers with MF finishes include, copy paper, grocery bag stock and butcher paper.

MG Paper: Dried by a Yankee Dryer

Rather than using multiple dryer cans to dry the paper, MG Paper is dried by one very large drier can called a “Yankee dryer”. The Yankee dryer is typically between 15’ and 22’ in diameter. By sticking a wet paper on a smooth Yankee dryer, and doing all of the drying from one side of the paper, the paper becomes smooth on one side. To get the same effect yourself, spray a mist of water on a piece of copy paper. Then use a clothes iron and gently press the iron to the paper. You will notice that the side you dry becomes smooth. A Yankee dryer has the same effect.

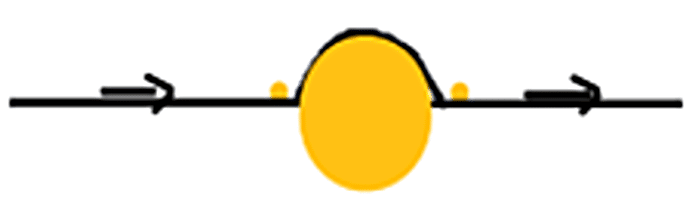

The diagram below shows how the web of paper passes over the Yankee dryer, which does all of the drying from one side of the paper.

Which is Better: MG or MF Paper?

People often ask whether MG paper is better than MF paper. The answer to that question? It depends! Although a brand-new MG Kraft Paper Machine was commissioned in Europe recently, the majority of new papermaking equipment produces MF paper. There are certain efficiency advantages to MF Paper and having paper with a similar smoothness on both sides is desirable in many applications.

However, MG Paper has advantages as well:

- The smooth surface is ideal when putting coatings down because the coatings do not dive into the sheet. Therefore, the MG side of paper is often used for printing and coating.

- Additionally, in lighter basis weights, there is often more MG capacity available because many of the machines built during the 40’s, 50’s and 60’s were MG machines that were designed for the one-time-carbonizing market. In that market in particular, the paper needed an MG surface to prevent the ink from diving into the sheet.

Conclusion: MG Paper is Preferred for Many Applications

MG Paper is especially smooth on one side while MF paper is equally smooth on both sides of the paper due to the drying processes that the papers go through during production. No coatings or waxes are used to make MG Papers. The smooth surface on MG Paper is preferred for some coating and printing applications. Contact Flexlink today to find out which paper is best for your application.